Methane Pyrolysis with Biomethane: A Carbon-Negative Pathway for Hydrogen Production and Carbon Sequestration

As the world moves towards decarbonization, the role of hydrogen as a clean energy carrier is gaining increasing attention. Hydrogen can replace fossil fuels in many industries, from transportation to heavy industry, with zero emissions when used in fuel cells or combustion. However, the production of hydrogen itself poses significant challenges, especially regarding carbon emissions and economic viability. Traditionally, hydrogen is produced through steam methane reforming (SMR), which emits large amounts of CO₂. While green hydrogen produced by water electrolysis using renewable energy is emerging as a clean alternative, another lesser-known approach offers the promise of low-emission hydrogen: methane pyrolysis using biomethane as the feedstock.

This article explores how methane pyrolysis using biomethane offers an exciting carbon-negative solution, compares it to traditional carbon capture and storage (CCS) methods, and highlights the potential economic, environmental, and cost advantages of this technology.

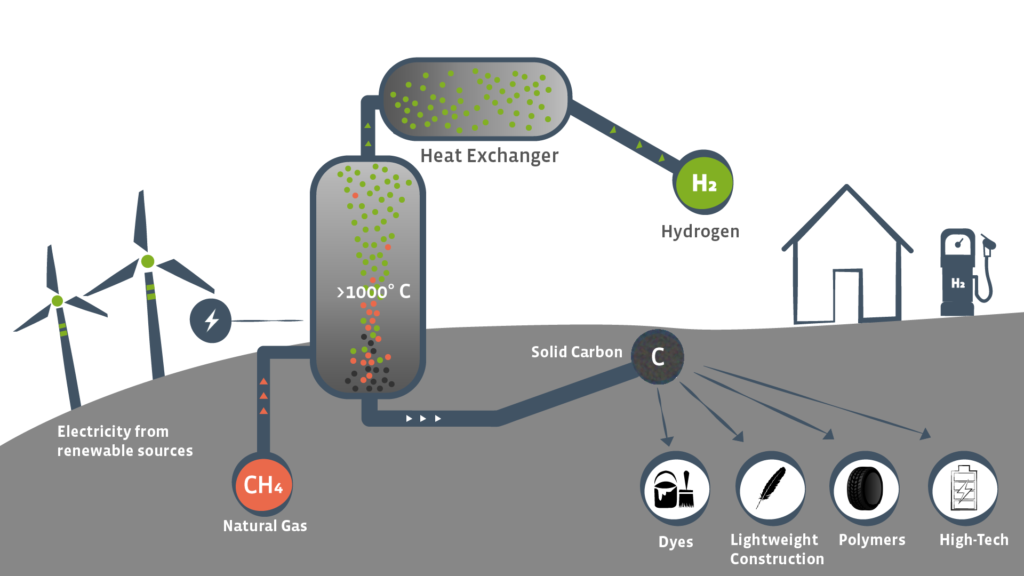

Methane Pyrolysis: The Basics

Methane pyrolysis, also known as “methane splitting,” is a process that breaks down methane (CH₄) into solid carbon and hydrogen in the absence of oxygen. The process takes place at high temperatures, typically between 700–1,500°C, and is endothermic, meaning it requires a significant amount of heat input. The key advantage of this process is that it produces hydrogen without generating carbon dioxide emissions, unlike traditional methods.

When using biomethane—a renewable form of methane derived from organic waste or agricultural residues—as the feedstock, methane pyrolysis becomes even more compelling. Not only does it avoid CO₂ emissions, but it also acts as a form of carbon sequestration, since the carbon from biomethane is converted into a solid form rather than being released into the atmosphere as CO₂. This aligns with the principles of LULUCF (Land Use, Land-Use Change, and Forestry) carbon sequestration, contributing to a negative carbon balance.

Economic and Cost Considerations

The economic viability of any energy production technology is a critical factor for its adoption. Methane pyrolysis with biomethane offers several cost advantages that can make it competitive with other hydrogen production methods.

- Capital Expenditure (CapEx):

- Methane Pyrolysis with Biomethane: The initial capital investment includes the cost of pyrolysis reactors capable of operating at high temperatures and handling solid carbon byproducts. While these reactors are specialized, they are generally less complex than the electrolyzers used in water electrolysis for green hydrogen production. Moreover, the modular nature of pyrolysis reactors allows for scalable deployment, reducing upfront costs for smaller operations.

- Comparison with Other Methods: SMR plants with CCS technology require significant capital investment for both the reforming process and the CO₂ capture and storage infrastructure. Water electrolysis systems are also capital-intensive due to the high cost of electrolyzers and the need for large-scale renewable energy installations.

- Operational Expenditure (OpEx):

- Energy Costs: Methane pyrolysis is energy-intensive due to the high temperatures required. However, if waste heat recovery systems are employed, overall energy efficiency can be improved, reducing operational costs. Additionally, using low-cost renewable energy or excess grid electricity during off-peak hours can further lower energy expenses.

- Feedstock Costs: Biomethane can often be sourced from local waste streams, agricultural residues, or landfill gas, sometimes at a lower cost than natural gas. In some cases, producers may receive tipping fees or subsidies for processing waste materials, effectively reducing feedstock costs.

- Byproduct Revenue: The solid carbon produced can be sold into various markets (e.g., carbon black for tires, graphite for electronics, construction materials), generating additional revenue streams that offset operational costs.

- Levelized Cost of Hydrogen (LCOH):

- Methane Pyrolysis with Biomethane: Studies estimate the LCOH for methane pyrolysis to be competitive with SMR, ranging from $1.5 to $3 per kilogram of hydrogen, depending on scale and technology maturity. When factoring in revenues from solid carbon sales and potential carbon credits for negative emissions, the effective LCOH can be even lower.

- Comparison with Other Methods: SMR without CCS typically has a lower LCOH, around $1 to $1.5 per kilogram, but with significant CO₂ emissions. Adding CCS increases the LCOH to approximately $2 to $2.5 per kilogram. Green hydrogen via electrolysis has an LCOH ranging from $4 to $6 per kilogram, largely dependent on renewable electricity costs.

- Carbon Credits and Incentives:

- Methane pyrolysis with biomethane can generate carbon credits due to its carbon-negative footprint. In regions with carbon pricing mechanisms or emission trading systems, these credits can provide substantial additional revenue. Governments may also offer incentives or subsidies for carbon-negative technologies, improving economic viability.

Comparing Methane Pyrolysis with Biomethane to Other CCS Methods

To understand the true potential of methane pyrolysis, it is important to compare it with other widely-discussed carbon capture and storage (CCS) methods, such as Direct Air Capture (DAC) and industrial CCS. Each method has its own infrastructure requirements, process efficiencies, market opportunities, and cost implications.

1. Infrastructure Needs and Costs

- Methane Pyrolysis with Biomethane: Requires investment in pyrolysis reactors and solid carbon handling systems. However, these are less complex than the equipment needed for DAC or industrial CCS. The modularity of pyrolysis plants allows for incremental scaling, spreading out capital costs over time. Sourcing biomethane locally can reduce transportation infrastructure costs.

- Direct Air Capture (DAC): Involves high capital costs for large-scale installations that require significant land area and complex equipment to process large volumes of air. The energy requirements for DAC are substantial, leading to high operational costs. Additionally, infrastructure for CO₂ compression, transport, and storage adds to the overall expense.

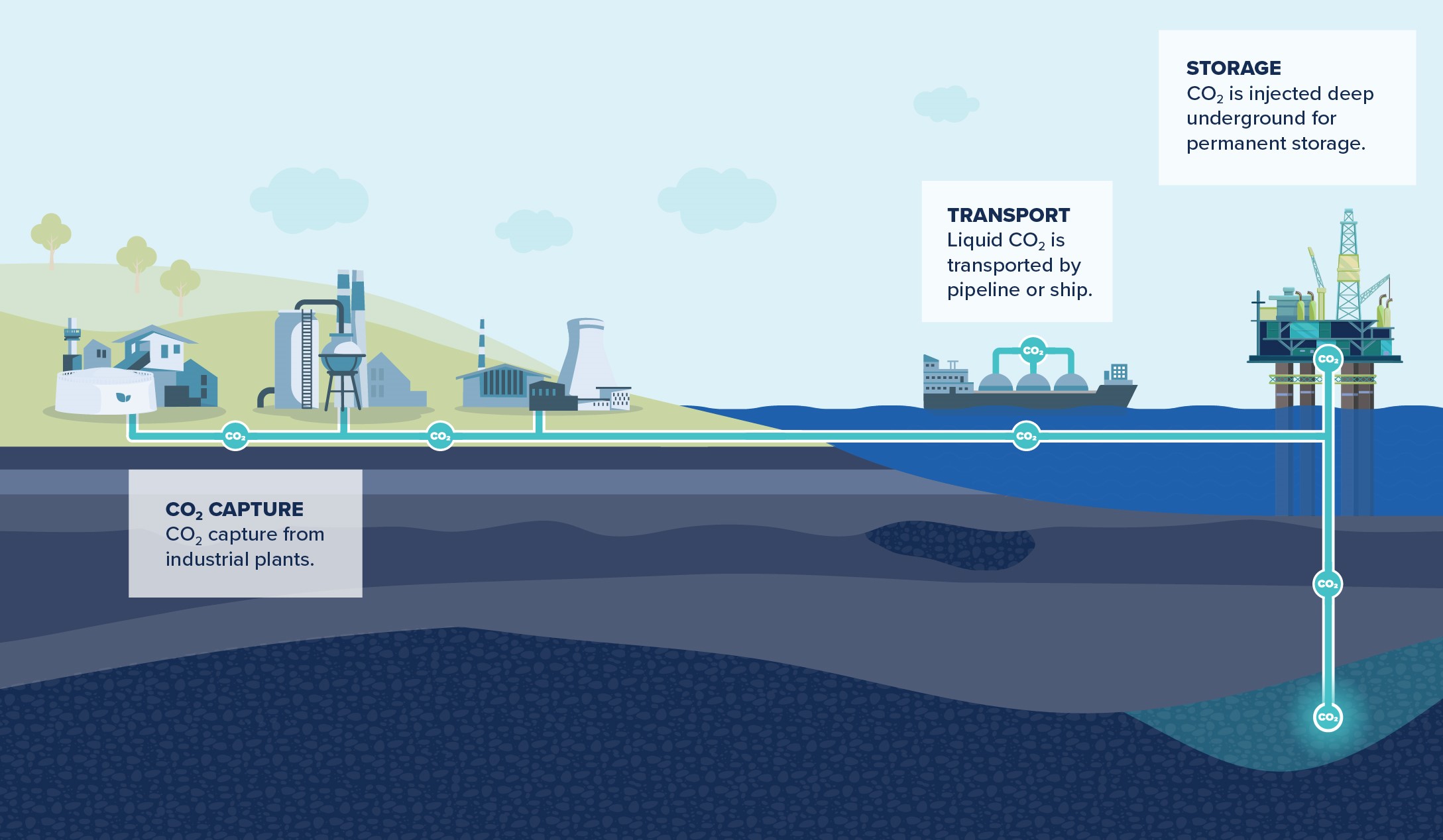

- Industrial CCS: Requires retrofitting existing industrial facilities with CO₂ capture equipment, which can be technically challenging and costly. The transportation and storage infrastructure for CO₂ (pipelines, injection wells) represents a significant capital investment with long-term maintenance costs.

2. Process Efficiency and Operational Costs

- Methane Pyrolysis with Biomethane: Offers moderate to high hydrogen yield efficiency (50-75%). Operational costs are influenced by energy consumption for heating and reactor maintenance. However, energy costs can be mitigated through heat recovery and utilizing lower-cost renewable energy. The management of solid carbon is less costly than handling gaseous CO₂.

- Direct Air Capture (DAC): Has low process efficiency due to the low concentration of CO₂ in the air (~0.04%). The operational costs are high because of the large energy input required for CO₂ capture and regeneration of absorbent materials. Energy costs dominate the operational expenditure.

- Industrial CCS: Operational costs include energy for CO₂ capture, compression, and transport. Capturing CO₂ from industrial processes can be energy-intensive, especially when dealing with low-concentration streams. Maintenance of capture equipment and CO₂ pipelines also adds to operational expenses.

3. Products to Offer and Revenue Potential

One of the significant advantages of methane pyrolysis with biomethane over other CCS methods is its ability to generate marketable products.

- Methane Pyrolysis with Biomethane:

- Hydrogen (H₂): Generates revenue from the sale of hydrogen, which has growing demand across multiple sectors.

- Solid Carbon: Provides an additional revenue stream through the sale of carbon byproducts. Depending on the quality and form of the carbon, it can be used in various applications, potentially commanding high market prices.

- Carbon Credits: As a carbon-negative process, methane pyrolysis can earn carbon credits or subsidies, adding to revenue.

- Direct Air Capture (DAC):

- CO₂ Utilization: Limited opportunities exist for utilizing captured CO₂, such as in EOR or production of synthetic fuels, but these markets are relatively small and not always economically viable.

- Carbon Credits: DAC may earn carbon credits, but the high costs often outweigh the revenues from credits alone.

- Industrial CCS:

- CO₂ Utilization: Similar to DAC, limited opportunities for CO₂ utilization exist.

- Avoided Emission Penalties: CCS can help industries avoid carbon taxes or penalties, indirectly saving costs but not generating direct revenue.

4. Environmental Impact and Carbon Sequestration

- Methane Pyrolysis with Biomethane: Provides a carbon-negative solution by sequestering biogenic carbon in solid form. The environmental risks associated with storing solid carbon are minimal compared to underground CO₂ storage. The process contributes to a reduction in greenhouse gas concentrations while producing valuable products.

- Direct Air Capture (DAC): While it captures atmospheric CO₂, the environmental benefit is offset by the high energy consumption, which must be met by renewable sources to maintain a net positive impact. Long-term CO₂ storage poses risks of leakage and requires monitoring.

- Industrial CCS: Reduces CO₂ emissions from industrial sources but relies on the effectiveness and integrity of CO₂ storage sites. Potential risks include leakage and induced seismicity, which can have environmental and public safety implications.

Cost-Benefit Analysis

When considering the overall costs and benefits, methane pyrolysis with biomethane stands out:

- Lower Capital Costs: Compared to DAC and industrial CCS, the capital costs for methane pyrolysis are lower due to simpler infrastructure requirements and the potential for modular deployment.

- Operational Cost Efficiency: Operational costs are offset by revenue from hydrogen and carbon byproducts, as well as potential carbon credits.

- Market Demand: There is a growing demand for both hydrogen and carbon materials, enhancing the economic case for methane pyrolysis.

- Environmental and Regulatory Benefits: The carbon-negative nature of the process positions it favorably in regulatory environments increasingly focused on emissions reduction, potentially unlocking subsidies and favorable policies.

Challenges and Considerations

Despite the promising economic and environmental advantages, several challenges need to be addressed:

- Technology Maturity: Methane pyrolysis is less mature than SMR or electrolysis technologies. Scaling up from pilot projects to commercial-scale operations requires investment and technological advancements.

- Market Development for Solid Carbon: The market for large volumes of solid carbon needs to be developed. If supply exceeds demand, prices may drop, affecting revenue projections.

- Policy and Regulatory Support: Government policies play a crucial role in the adoption of new technologies. Supportive policies, carbon pricing mechanisms, and incentives are essential to make methane pyrolysis economically competitive.

- Feedstock Availability: The availability and cost of biomethane can vary regionally. Ensuring a consistent and affordable supply is critical for operational stability.

Conclusion: Methane Pyrolysis with Biomethane – A Carbon-Negative and Economically Viable Future

Methane pyrolysis with biomethane presents a promising, carbon-negative solution for hydrogen production and carbon sequestration. Economically, it offers competitive capital and operational costs, potential revenues from multiple products, and opportunities to earn carbon credits. Compared to Direct Air Capture and industrial CCS, methane pyrolysis with biomethane is more energy-efficient, produces marketable outputs, and provides a stable form of carbon sequestration without the need for complex and costly underground storage.

As the world transitions to a more sustainable energy system, technologies like methane pyrolysis will play a critical role in reducing emissions and creating a circular economy around hydrogen and carbon products. By utilizing biomethane, this process offers a unique opportunity to not only decarbonize energy production but also help mitigate climate change by capturing and storing carbon in a stable and economically viable form.

Investment in research and development, supportive policies, and market development for carbon products will be essential to fully realize the potential of methane pyrolysis with biomethane. With these in place, methane pyrolysis could become a cornerstone technology in the global effort to achieve carbon neutrality while meeting the growing energy demands of the future.